Concurrent Engineering Is Best Described as

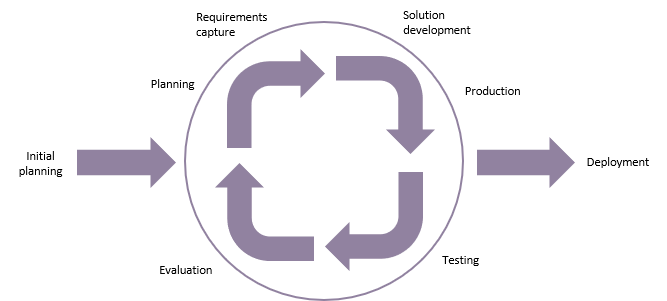

Also known as simultaneous engineering or integrated product development concurrent engineering is an approach that utilises parallel project life cyclesto speed up product development. Concurrent engineering also known as simultaneous engineering involves a parallel development across product life cycle activities from conception through disposal including quality cost schedule and user requirements using technologies such as CAD and manufacturing.

Concurrent Engineering An Overview Sciencedirect Topics

How to Make the Best Use of Product Data Management.

. By Nicola Accialini capability management culture innovation new product development quality management. Using shared databases customers designers and production managers can simultaneously. Often described as one central point of truth.

Concurrent engineering is best described as. Concurrent Engineering is a strategy formulated in the late 1980s to meet the industrys growing need for lead time reduction time to market in addition to cost control and quality improvement. Posted by Emma Rudeck on 29-Jan-2014 105800.

Jennifer Moore Cohort 11 Prod-Ops Mgmt Quiz 2 24 Jan 2017 b. It embodies team values of co-operation trust and sharing in such a manner that decision making is by consensus involving all perspectives in parallel from the beginning of the product life cycle. Concurrent engineering is best described as Answer.

While Taiichi Ohno and others have meticulously described the TPS the Toyota development system has not been well documented4 Indeed Toyota does not use many of the practices often considered critical to successful concurrent engineering and associated with Japanese manufacturers. Concurrent engineering also known as simultaneous engineering is a method of designing and developing products in which the different stages run simultaneously rather than consecutively. Concurrent Engineering CE is a systematic approach to integrated product development that emphasises the response to customer expectations.

Rome Italy 17-19 June 2002 Concurrent Engineering in Total Quality Management Environment Manoochehr Najmi1 and Ip-Shing Fan2 1 Graduate school of Management and Economics Sharif University of Technology Tehran Iran mnajmisharifacir 2 Department of Enterprise Integration Cranfield University Beds UK isfancranfieldacuk Abstract The essence of. View Quiz3_MBA6205docx from MBA 6205 at University of Houston Downtown. MBA 6205 - QUIZ 3 1.

Concurrent engineering is best described as. The keys to simultaneous engineering are teamwork and communication among the different specialists who will be working on the project team to develop both the product and its supporting processes. Concurrent Engineering can be described as the effort.

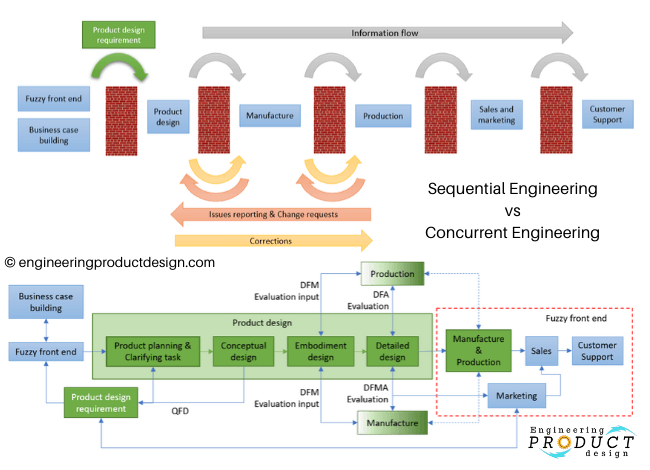

An historical approach to designing and developing new products that lately is being abolished as bad business practice because of its lengthy time to introduce new. It evolved during the late 1980s and in 1992 an article in Machine Design1illustrated it with this simple diagram. This demonstrates that in Concurrent.

Concurrent engineering is best described as. Its development teams are not colocated. Concurrent engineering is a team-based approach to product development in which all stakeholders are involved in the process from the outset.

Basically concurrent engineering is a design philosophy that seeks to improve the quality and usability of products improve customer satisfaction reduce costs and ease the transition of a new product from design to manufacturing. Concurrent Engineering is a long term business. According to practitioners of this type of business strategy VMC can easily benefit from concurrent engineering due to the following reasons eFunda 2009.

Concurrent engineering is best described as. The simultaneous design and development of all the processes and information needed to manufacture a product to. The definition of Concurrent Engineering that we have adopted for the Concurrent Design Facility is.

Manufacturing Engineering New Product Development New Product Development Risk Management Strategy. Page 1 of 2. The simultaneous design and development of all the.

If this is not widely understood arrange a DFMCE. A sequential attempt among functional disciplines to design new products. It would be best to use concurrent engineering to eliminate waste and to speed up delivery time while producing high-quality products.

Simultaneous engineering goes by other names such as concurrent engineering design for manufacturing design for assembly and parallel release. It decreases product development time and also the time to market leading to improved productivity and reduced costs. Concurrent Engineering CE is a systematic approach to integrated product development that emphasizes the response to customer expectations.

3 things to know. The goal is to design a product that meets as many of the stakeholder requirements as can be accommodated and which can be produced at the target cost and quality level with minimal expense and delay. The simultaneous design and development of all the processes and information needed to manufacture a product to.

Webinar training or distribute the 600 page 2022 DFM book. Concurrent engineering CE is a mechanism that can reduce uncertainty and equivocality and improve an organizations competitive capabilities. Concurrent engineering has been defined as the parallel execution of different development tasks in multidisciplinary teams with the aim of obtaining an optimal product with respect to functionality quality and productivity Rolstadås 1995.

Concurrent Engineering Blog. Simultaneous design and development Sequential product development projects are likely to have ____________ development costs and ____________ development times than concurrent engineering product development projects. Concurrent engineering goes beyond diagrams charts and algorithms.

It embodies team values of co-operation trust and sharing in such a manner that decision making is by consensus involving all. Since this is the worst possible time to fire-fight production or ramp problems on the floor as shown in the two upper graphs below companies shoul implement Concurrent Engineering which can be learned and one in remote teams using Zoom or MS.

Concurrent And Sequential Engineering New Product Development

Concurrent Engineering Praxis Framework

Concurrent Engineering Principle Tools Techniques Advantages

0 Response to "Concurrent Engineering Is Best Described as"

Post a Comment